Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

New AC Cable Standards for Photovoltaic Systems Released: PPP58216 Launched

Date: January 11, 2023

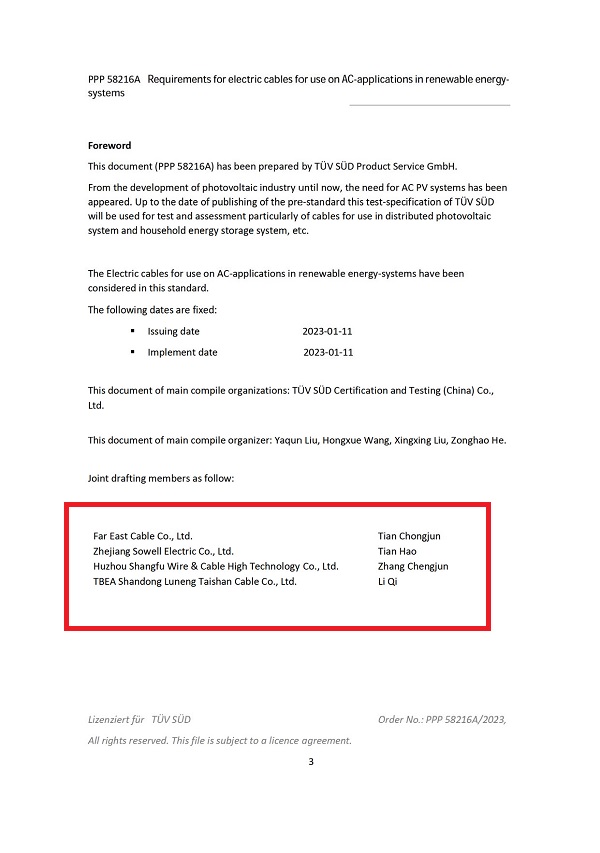

The recent release of the PPP58216 standard marks a significant milestone in renewable energy infrastructure, establishing critical guidelines for AC cables in photovoltaic (PV) systems. Spearheaded by TUV SUD, Zhejiang Sowell Electric Co., Ltd. (Sowellsolar), and other industry leaders, this standard ensures safer, more efficient power transmission within PV installations, propelling the renewable energy sector into a new era of reliability and safety.

Why PPP58216 Matters for Photovoltaic (PV) Systems

With renewable energy installations expanding rapidly, PV systems face increasing demands for durability, safety, and efficiency. This new standard, PPP58216, addresses these challenges by setting rigorous standards for AC cable performance in PV systems. AC cables in these systems must withstand extreme conditions, such as UV exposure, high temperatures, and electrical stress, while consistently transmitting power efficiently. The PPP58216 provides a framework to address these issues head-on, helping manufacturers produce higher-quality cables and ensuring safer, longer-lasting PV installations.

TUV SUD’s Role in Standardizing PV System Safety

As a renowned certification and testing organization, TUV SUD has long been at the forefront of safety and quality assurance in the electrical and renewable energy industries. With extensive experience in testing and certifying products to meet international standards, TUV SUD has played a key role in shaping the PPP58216 standard. By collaborating with experts in photovoltaic technology and electrical infrastructure, TUV SUD has contributed to creating a standard that enhances reliability while promoting sustainable practices.

Dr. Markus Fichtner, a senior engineer at TUV SUD, emphasized the importance of this standard:

“The PPP58216 standard will help drive the PV industry toward greater efficiency and safety. It ensures that only cables meeting stringent performance requirements are utilized in PV systems, ultimately supporting the growth of a more sustainable energy future.”

Zhejiang Sowell Electric Co., Ltd.: Leading the Way in Photovoltaic Innovation

Zhejiang Sowell Electric Co., Ltd., also known as Sowellsolar, has emerged as a leading manufacturer of electrical components for renewable energy systems. The company’s extensive research and development focus on creating innovative, high-performance cables designed to meet the unique demands of photovoltaic applications. As a co-contributor to the PPP58216 standard, Sowellsolar has demonstrated its commitment to advancing industry practices, improving PV system safety, and ensuring that renewable energy solutions meet the highest global standards.

Mr. Lin Kai, CEO of Sowellsolar, highlighted the company’s dedication to the renewable energy sector, stating:

“Our commitment to producing world-class photovoltaic cables aligns with the vision of PPP58216. We are proud to have contributed to this standard, which will enhance the efficiency and reliability of PV systems globally.”

Key Features and Requirements of the PPP58216 Standard

The PPP58216 standard introduces several essential criteria for AC cables used in photovoltaic systems. These requirements address critical performance and safety aspects, including:

-

Temperature Resistance

Cables must withstand high temperatures without degradation, a crucial factor for outdoor PV installations in hot climates. -

UV and Weather Protection

The standard mandates UV-resistant materials to prevent cable degradation due to prolonged sun exposure. -

Electrical Insulation and Fire Resistance

Enhanced insulation and fire resistance help to prevent short circuits, fire hazards, and other safety risks. -

Mechanical Durability

The cables must endure mechanical stresses, including bending and stretching, that are common in PV system installations. -

Corrosion Resistance

Corrosion-resistant materials are required to ensure the cables remain functional in various environmental conditions, including areas with high humidity or salt exposure.

Impact of PPP58216 on the Renewable Energy Industry

With the establishment of this standard, the PPP58216 sets a benchmark that cable manufacturers must meet, fostering a culture of quality and safety across the renewable energy industry. The standard’s influence will likely extend beyond PV systems, encouraging advancements in cable design for all types of renewable energy applications.

Additionally, the introduction of PPP58216 brings increased confidence to investors, installers, and consumers, as they can be assured that PV systems meeting this standard adhere to the highest quality levels. This contributes to a more sustainable and resilient energy infrastructure worldwide, as reliable PV systems reduce the risk of system failures, costly repairs, and potential safety hazards.

Future of Photovoltaic Cables and Compliance with PPP58216

Moving forward, the PPP58216 standard will serve as a guideline for manufacturers aiming to align with the latest quality and performance metrics. Compliance with this standard is expected to become a key requirement for companies involved in PV system production, as the industry continues to prioritize quality and long-term sustainability.

As the renewable energy sector continues to grow, additional updates to this standard may arise, addressing emerging challenges and advancing technology in photovoltaic systems.

Conclusion

The release of the PPP58216 standard represents a significant step toward achieving a safer, more reliable, and sustainable energy future. By setting rigorous criteria for AC cables in PV systems, TUV SUD, Zhejiang Sowell Electric Co., Ltd., and other industry contributors have laid the foundation for a robust infrastructure that will support the renewable energy transition.

With this standard now in place, photovoltaic system operators, manufacturers, and other stakeholders can focus on achieving high efficiency and safety while contributing to a greener future.